Introduction

Nearly all of our products are sold with an Uninterruptable Power Supply (UPS) because customers need phone service for emergency voice calls, which we refer to as "lifeline service". Batteries are used for energy storage in all of our UPS hardware we sell. I do not know a single engineer who regularly deals with batteries that likes them. They are the biggest pain I deal with. Here is my summary of complaints:

- They are expensive.

Batteries often contain materials that are very expensive. Battery cost is strongly affected by commodity prices. It was not long ago that a commodity price bubble caused me great pain as I tried to keep my unit product cost down. - They require replacement at regular intervals (every 3 to 5 years) to ensure they work when needed

- There are always safety issues to address

Look at the history of Li-ion batteries and their tendency to catch fire. Many battery chemistries emit explosive gases (e.g. lead-acid batteries emit hydrogen when being charged). - They often contain materials that are expensive to dispose of.

Batteries often contain materials like lead (e.g. lead-acid batteries) or cadmium (eg. Nicad batteries). These are poisonous elements that are expensive to dispose of safely. - Charging is often a complicated operation.

- Battery performance is strongly temperature dependent.

Our UPS vendor has a "low battery" alarm that supposedly tells the customer when the battery capacity has been reduced to 20% of its rating. This is an extremely deceptive alarm. I have spent much time trying to accurately predict remaining battery capacity and have not been totally successful. This is a complicated question because a battery is a chemical beast that is subject to temperature and aging effects that make accurate prediction of it remaining capacity difficult.

Today, our customer service group asked me to explain what "20% capacity remaining" really means. All I could do was sigh and give the following answer.

Analysis

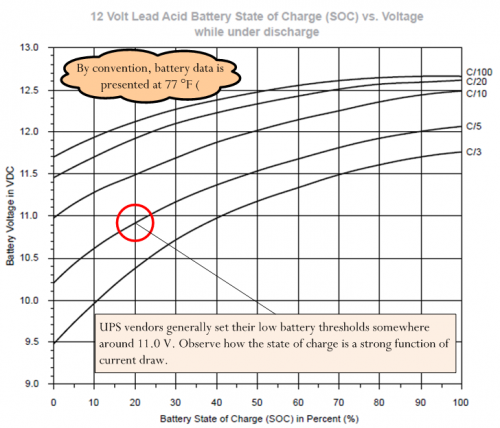

Most UPS hardware tries to estimate their battery's state of charge by measuring the battery terminal voltage. Figure 1 shows the terminal voltage versus state of charge voltage for a 6-cell, 12 V lead-acid battery.

People unfamiliar with batteries see that there are multiple curves that are labeled with things like "C/100" or "C/3". These curves represent the current load the battery is under load. The ratio "C/T" represents represents the capacity of the battery in amp-hours (C) and the discharge time (T).

| Eq. 1 |

where C is the battery capacity in amp-hours and TDischarge is the discharge time.

The UPS we use has its low battery alarm set to activate when the terminal voltage drops below 11.0 V. However, an 11.0 V terminal voltage only represents 20% capacity when the battery load is C/5. In my application, the load is C/10. This means that in my application the low battery alarms is asserted when the battery is almost completely discharged. This has caused some issues for customers who want to depend on that last 20%. Unfortunately, they cannot depend on that battery having any capacity left when the low battery alarm is activated.

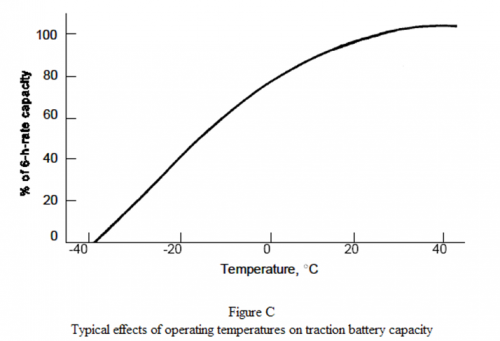

Temperature also complicates the situation. Everything I have said above assumes a temperature of 77 °F (25 °C). Battery capacity depends strongly on temperature, which is shown by Figure 2.

If your UPS is at a temperature other than 77 °F, you will need to compensate for the temperature variation.

Battery capacity is also a function of the age and charging history of the battery. Older batteries do not have as much capacity as new batteries because of corrosion effects. Batteries that have been through many charge and discharge cycles have less capacity than new batteries because battery capacity degrades with each discharge/charge cycle.

Conclusion

Accurately predicting reserve battery capacity is a complicated thing. I try to avoid it whenever I can.