Quote of the Day

Do something instead of killing time. Because time is killing you.

— Paulo Coelho

Introduction

I was listening to a radio program called Planet Money today that was discussing how how intricate the infrastructure is for making something as simple as a T-shirt. They were making a T-shirt that they would sell to raise money to help the garment workers in Bangladesh (see Figure 1). The money required for this effort was raised on Kickstarter.

Here are some basic facts presented presented during the presentation:

- The cotton used to make the T-shirt comes from very high-tech farms in the United States.

The farms were operated by a small number of workers who really were technicians that supervised the operation of large machines.

- The best cotton must never be touched by human hands.

The highly automated US farms are ideal for producing high quality cotton.

- The cotton fabric was made into T-shirts by workers in Bangladesh.

These are very low paid workers -- $80 per month.

- The T-shirts are shipped around the world on container ships.

The development of container ships has enabled the efficient shipping of all sorts of products around the world -- including T-shirts.

I found the information about cotton to be the most very interesting. Here is a video from the SmartPlanet web site on the cotton-portion of the story.

I know NOTHING about clothing and fabric. Let's see if I can use some math and a little information from the web to learn something about fabric and T-shirts.

Background

There were four key numbers that I need to know my analysis:

- It takes 6 miles of cotton thread to make a T-shirt (Source).

I have seen this number quoted from a number of sources, including the radio broadcast we are discussing here.

- The density of cotton is 1.55 gm/cm3 (Source).

I calculated the average of the minimum and maximum values listed.

- Making a T-shirt requires about 1 square yard of material (Source).

The pattern I am looking at uses 1.25 yards. I am assuming that there is some waste and the T-shirt ends up containing about 1 square yard of fabric.

- A typical T-shirts weighs 6 ounces.

I just put my T-shirt on a food scale. The T-shirt was a short sleeve, V-neck style.

Let's see what we can learn from these numbers.

Analysis

Thickness of the Thread

A Little History

I deal with glass fiber all today, which is very fine (~125 μm). I show a cross-section of optical fiber in Figure 2 (Source). Fortunately, I have all sorts of fancy instruments that allow me to measure tiny things.

This has not always been the case for people who work with fiber. With respect to textiles, people have been producing fabric for thousands of years, but they had no way to accurately measure the thickness of the tiny thread they were using. As people do, they developed a workable substitute metric. They simply would run off a specified length of thread and weigh it (or determine its mass). As long as the thread was constructed consistently, this weight (mass) would be proportional to the diameter of the fiber and could be used as a substitute for the diameter. The metric standard is mass in grams for 9000 meters of fiber, which is called the denier. The Imperial unit is called the yield and is expressed in term of yards of thread per pound. Note how the dimensions (mass, length) of yield are the inverse of those for denier.

Modeling Fiber As A Cylinder

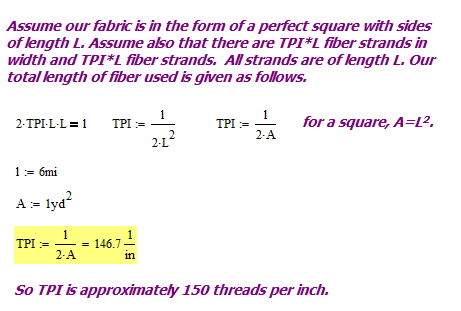

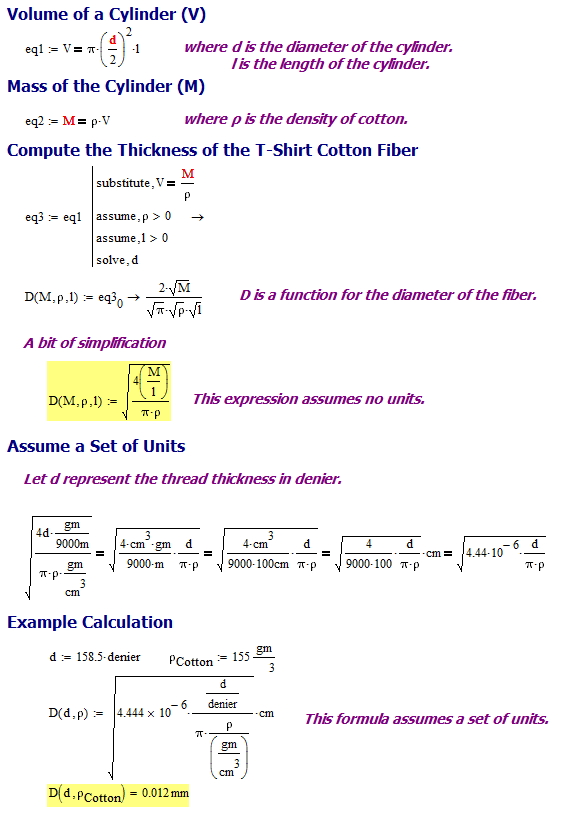

If we model a thread as a cylinder, we can estimate the thickness of the thread to be 0.12 mm, as shown in Figure 3.

Threads thickness is not normally specified in terms of a linear dimension like centimeters, but instead in units of denier or yield. A simple unit conversion shows us that T-shirt fiber has a thickness of 158 denier (Equation 1).

| Eq. 1 |

On a related note, one can convert from a thread thickness specified in denier to centimeters. The Wikipedia give Equation 2 for performing the conversion.

| Eq. 2 |

where

is the diameter of the thread [cm].

is the density of the fiber material [gm/cm3].

- d is the thickness of the fiber expressed in denier [gm/9000 m].

I derive this formula in the Appendix.

Thread Count of the T-Shirt Fabric

The thread count of fabric is defined as:

Thread count or threads per inch (TPI) is a measure of the coarseness or fineness of fabric. It is measured by counting the number of threads contained in one square inch of fabric, including both the length (warp) and width (weft) threads.

Figure 4 shows how I can estimate the number of threads per inch of T-shirt fabric.

The Wikipedia says that "standard" cotton fabric has a thread count of 150 threads per inch. So the number I came up with here is reasonable.

Conclusion

Just a quick post showing how the fabric for a T-shirt is measured.

Appendix:Wikipedia Thread Thickness Formula Derivation

Figure 5 shows the derivation of Wikipedia's formula for converting denier to centimeters.

For "1 of 13". I'm a lay person and do understand the equations used. Even though I hold a Masters degree it is in education, but not math.

My question is the following: When wishing to order a "heavyweight" cotton T shirt, what weight would show it to be a "heavy" vs. "medium" or "light"?

Please advise and thank you......... Bruce

Pingback: Cannon Bore Measured in Pounds | Math Encounters Blog

Fabric density refers to the number of yarns per unit area of the fabric. Fabric Density Meter used to test the number of yarn of all fabrics. If you want to know more, please click on https://www.testextextile.com/product/fabric-density-glass-tf122/