Quote of the Day

History is a tool used by politicians to justify their intentions.

— Ted Koppel

I have been rather frustrated lately with the number of field failures I have encountered that are related to the humble cable tie (Figure 1 - Source).

There are several problems related to cable ties.

- They are easy to over-tighten

Many people tighten the cable ties so tightly that the damage the insulation of the wires.

- If your cables move, the cable ties tend to "bite" into the insulation.

I just encountered this problem in our office. Instead of standard whiteboards for marking, we use SMART boards. One of our SMART boards behaved very erratically. As we investigated, we discovered that the cable tie used to secure a cable had abraded the insulation off of some wiring.

- They can be used to tie cables in positions that put strain on connectors.

This problem has created some real problems for me. The cable riggers pulled that cables at very odd angles which put strains on Printed Circuit Boards (PCBs). PCBs are not designed to be under mechanical strains and we have seen issues.

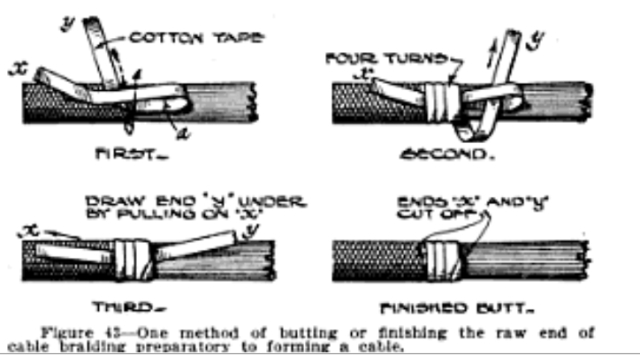

I started to look around for good examples of cable rigging that did not use cable ties. I soon found that the folks at NASA have done some very nice rigging on their Mars rovers. Figure 2 shows one example. For a great discussion of rigging for Mars, see this forum discussion.

It is not hard to believe that NASA understands cable rigging. They have had some issues in the past and they learn from their mistakes (e.g. Space Shuttle and Apollo 1).

I have found some good aerospace reference material on rigging that I want to make more readily available. These methods seem very reasonable to me.

I will be using these standards in my engineering group for guidance. There are a number of vendors that put out rigging supplies. Here is one vendor recommended in the forum of Guild of Knot Tyers.

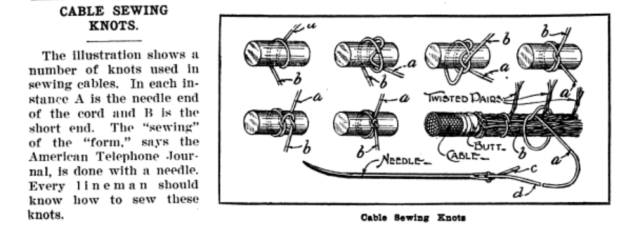

There is also some good material put out by the telecommunications companies -- some of this material is over 100 years old (Old 50 MByte Telephone Spec). For example, Figure 3 shows an approach from this old material that I still occasionally use.

In the old days, they even referred to sewing cables together (Figure 4).

On a personal note, I am a big knot person. Studying knots and their application have been a recreational activity of mine for years.

you should look at the inside wiring of a 100 year wooden wall phone. those wire wraps that extend the length of the wiring loom are a work of art.

If you have some pictures, I would love to post them. I document craftsmanship.

mathscinotes

Pingback: Old School Spacecraft Thermal Insulation | Math Encounters Blog

The guild of knot tyers website you linked, has this wonderful link to a physics website with extended (mcad document?) analysis of rock climbing ropes.

I am a rock climber and many years ago, built some Strain Guage based test gear for simple tests of climbing ropes,but this website has all sorts of much more interesting tests and calculations on rope static and dynamic models.

http://www.bigel-labs.de/3.Physik/RopeTests/web

Even UTS Testing is quite tricky: If you use a normal hydraulic material test machine, the sort you might find in a civil engineering /material science test lab, you soon realize the rope elongations at failure are so large you run out of range and there are all sorts of issues with how you attach the ropes, since you can't use normal sample grippers and any knots/wrapping on fixtures reduces strength.

That is a very interesting page on the physics of knots and I will need to go through it.

I really enjoy working with knots and rigging. Unfortunately, I have encountered many wiring problems associated with poor rigging.

mathscinotes

Pingback: Naked and Afraid Statistics | Math Encounters Blog