Quote of the Day

Life isn't about finding yourself. Life is about creating yourself.

— George Bernard Shaw:"

Introduction

Figure 1: 7.2 A-hr Sealed Lead Acid Battery.

I deal with a lot of battery issues. Our products generally ship with an Uninterruptible Power Supply (UPS) that contains a 7.2 A-hr Sealed Lead-Acid (SLA) battery (Figure 1). I occasionally hear customers say that we shipped them bad batteries. Since we charge the batteries just before shipment, I know the batteries left our facility functional and with a full charge. In every single case, the customer had not properly handled the batteries -- the batteries had become fully discharged because they had been stored for too long between charging cycles. A discharged lead-acid battery will eventually become sulfated -- a state where the battery plates are coated with a crystalline layer of lead sulfate and lead oxide. Some people refer to this layer as a "varnish" because sulfated plates look like they are coated with wood varnish. A sulfated battery usually is only good for recycling. See the Appendix of this post for a reference on the topic.

During a normal discharge cycle, lead-acid batteries form a layer of amorphous lead sulfate on their plates. Charging converts the amorphous form of lead sulfate back to lead. Unfortunately, when a discharged battery is stored for a long period of time (usually weeks or months), the amorphous lead sulfate changes into a crystalline form that cannot be converted back to lead through normal charging. This paper has great photos that actually show you the crystals that form.

When I first started this job, I would often go to the deployment sites to investigate reports of customers receiving dead batteries. My first customer visit was pretty typical. The customer was angry that all of his batteries were dead. I started my investigation by asking him how he handled his batteries. He told me that his UPS units were stored in warehouse prior to being installed. I asked him if I could visit the warehouse and he proceeded to take me to a large barn. The UPS units and their batteries were stored in the loft of the barn at a temperature of about 50°C (122 °F). They typically sat in the warehouse for three to four months before being deployed. The batteries were dying during that storage period. I told my customer that the batteries were not being stored according to the vendor's battery storage requirements. He said that no one ever told him what the battery handling requirements were and I needed to pay to replace every one of his failing batteries (including service call). I then reached into a UPS box and pulled out the battery handling specification that ships with every UPS. He seemed pretty sheepish after seeing that he had received thousands of battery handling instruction sheets. He had never actually looked in the boxes.

At room temperature, batteries can sit for months without a problem. However, batteries at high temperature can fail in a very short period of time. Let's examine this acceleration closer.

Background

Few batteries die a natural death -- most batteries are murdered. They are murdered by owners that charge them improperly, cycle them too deeply, let them sit discharged for too long, or store them at too high a temperature. Since our UPS units have built-in controllers and the units are rarely deeply discharged, the primary battery killer is heat.

Batteries are electrochemical machines. Chemical reactions govern how they work and chemical reactions govern how they fail. Chemical reactions exist within a battery that cause them to discharge while just sitting in storage. Other chemical reactions cause them to form crystalline lead sulfate. Both of these reactions are accelerated by temperature according to the Arrhenius equation, which I state in Equation 1.

| Eq. 1 |

|

where

Equation 1 tells us that increasing temperature produces an exponential increase in reaction rate. Let's examine how this reaction rate affects a battery that appears to just be sitting there -- it actually is experiencing an internal chemical reaction that is discharging the battery. I also want to examine a common rule of thumb for electrical engineers.

A battery at a temperature of T+10 °C self-discharges twice as fast as the same battery at a temperature of T.

Is this rule true? If it is true, the customer that I mentioned earlier who stored his batteries at 50 °C would see his batteries discharged in his warehouse within about two and half months. At that point, the sulphation process begins. His batteries were dying right before his eyes.

Analysis

Empirical Battery Discharge Data

All battery vendors publish self-discharge data for their products. Each battery vendor's products have different self-discharge rates because the rates are a function of how the plates are constructed (i.e. different lead alloys). Figure 2 shows a particularly well done self-discharge chart.

Figure 2: Sealed Lead Acid Battery Self-Discharge Graph.

Discussion

I am not an electrochemist and I will not discuss all the details of Equation 1, but we can learn some things from a qualitative examination of Figure 1.

- A lead-acid battery self-discharges over time.

- The chart shows that you do not want to let a battery discharge below 60% of its full capacity.

- A lead-acid battery can be stored for about a year at room temperature before it needs a recharge.

- At high temperature (i.e. >40°C), a battery self-discharges much more rapidly than at room temperature (~22 °C).

It is amazing how many batteries I have seen destroyed by high temperature. At one deployment site, I saw that the customer had over 900 batteries reported as failures. Every failed battery had been stored improperly and then installed in a private residence when fiber service was installed at that home. The UPS did a battery load test every ten days, so the battery would be reported as failed 10 days after it was installed, which means a technician had to physically go out to a person's home and replace the failed battery (often with another failed battery). This went on for a year.

I would not want to explain to my boss that I screwed up by not following the directions included with every battery. Replacing a battery is not cheap, and paying for a service call to install the battery is not cheap either. There were many tens thousands of dollars worth of avoidable problems at this one customer site alone.

Rule of Thumb Accuracy

Assume that we want to ensure that our batteries never drop below 60% of full charge. In Figure 1, we see that as the battery temperature raises from 30 °C to 40 °C, the self-discharge time reduces from 8 months to about 5 months, which is less than half. We also see that as the battery temperature raises from 25 °C to 40 °C, the self-discharge time reduces from 13 months to about 5 months, which is more than half. So the actual doubling (or halving) temperature difference is between 10 °C and 15 °C. So the rule of thumb appears to provide a pessimistic answer in this case, which is okay for a rule of thumb.

Note that the exponential function and the rule of thumb are only related approximately. The derivation in Figure 3 shows that the rule of thumb is only true for a limited range of values. However, the range of values is reasonable with respect to lead-acid batteries.

Figure 3: Derivation Showing Approximate Equivalence of Rule of Thumb and Arrhenius Equation.

The derivation shows that the 1/10.25 K is the proportionality "constant" for temperatures near 22 °C (room temperature) --the slow variation of the logarithm function helps us here. This means that the reaction rate roughly doubles for a 10.25 °C increase in temperature. The "constant" varies a bit across the temperature range of a battery. Figure 4 shows this variation. For a rule of thumb, it is not bad.

Figure 4: Variation in C parameter of Alternate Arrhenius Function.

Conclusion

As summer nears, I will again receive calls from people about dead batteries. I hope I can provide guidance to people on how to avoid a costly and avoidable error.

Appendix

Activation Energy

Figure 5 is an excerpt from a battery reference ("Valve-Regulated Lead-Acid Batteries" by David Anthony and James Rand) that provides a value for the activation energy for the self-discharge reaction in a lead-acid battery.

Figure 5: Activation Energy Reference.

Discussion of the Crystalline Layer

Figure 6 is an excerpt from page 16 of "Valve-Regulated Lead-Acid Batteries" by David Anthony and James Rand that discusses the formation of an insulating layer.

Figure 6: Reference on Forming an Insulating Layer That Renders Batteries Unchargeable.

Save

Save

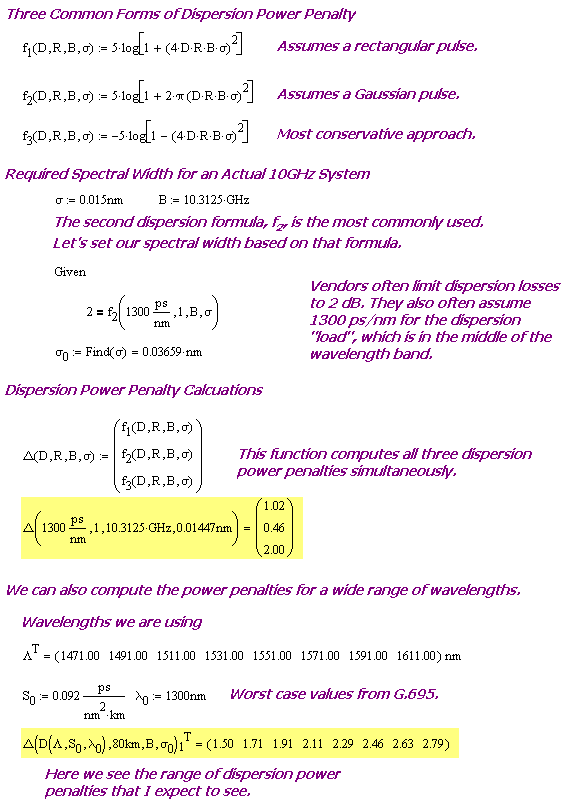

is the spectral width of the laser