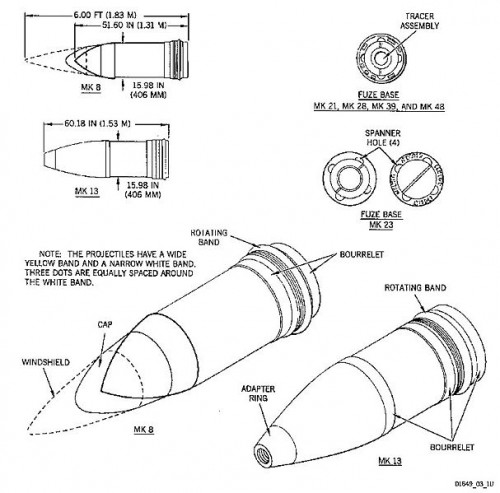

Introduction

As mentioned in a previous post, I am reading the book "Modern Practical Ballistics" by Pejsa. I have been working through some of the derivations in the book and they are interesting enough (at least to me) to be worth documenting here. One of these interesting derivations is an elegant result for the variation in projectile velocity versus range. Since all cartridge documentation include tables of velocity versus range, I have a wealth of data to compare to the equation's output. I love it when I can compare a model to lots of real data. Let's dig in …

Drag Coefficient

A projectile moving through air experiences drag. The force of drag slows the projectile and causes velocity to fall of as the projectile travels on it course. The Wikipedia contains a very good discussion of drag and I refer you to that article for greater details. However, I will review the relevant points to my discussion here quickly.

- Drag refers to forces that oppose the relative motion of an object through a fluid (a liquid or gas).

- Drag forces act in a direction opposite to the oncoming flow velocity. This means that there will be some minus signs in upcoming equations.

- Drag forces depend on velocity.

- For the purposes of this blog, I will be focusing on the drag a bullet experiences above the speed of sound. This is considered high velocity. There are ways to model drag at other velocities, but that is not my goal here.

The force that drag exerts on a bullet is given by the drag equation (Equation 1).

| Eq. 1 |

|

where

- Fd is the force of drag, which is by definition the force component in the direction of the flow velocity

- ρ is the mass density of the fluid

- v is the velocity of the object relative to the fluid

- A is the reference area

- cd is the drag coefficient

Understanding the drag coefficient cd is the most important part of this discussion. Equation 2 contains the definition of the drag coefficient.

| Eq. 2 |

|

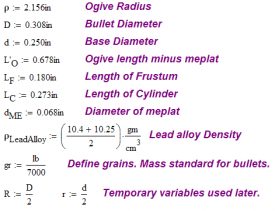

We need to make some observations about the drag coefficient.

- Below the speed of sound, the force of drag increases with the square of velocity.

- This means the drag coefficient is constant for velocities less than the speed of sound.

- Above the speed the speed of sound, the force of drag does not follow a square law.

- Therefore, the drag coefficient is NOT a constant in the transonic and supersonic regions.

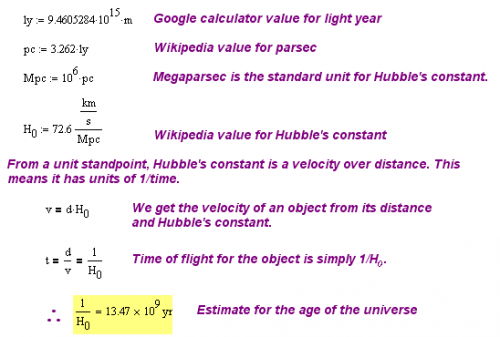

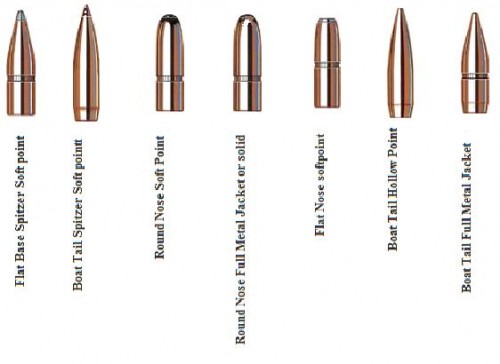

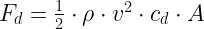

Figure 1 shows an example of the drag coefficient for the standard reference bullet, usually referred to as the G7 shape (see Figure 2).

Figure 1: Drag Coefficient Plot (Green Line) for a G7 Standard Projectile.

Note that Figure 1 also shows a blue line that demonstrates that the drag coefficient can be well approximated for velocities above the speed of sound (~1,126 ft/s feet per second) by an equation of the form  , where kd and n are projectile-specific constants.

, where kd and n are projectile-specific constants.

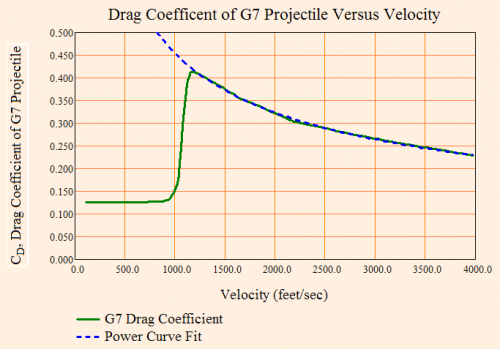

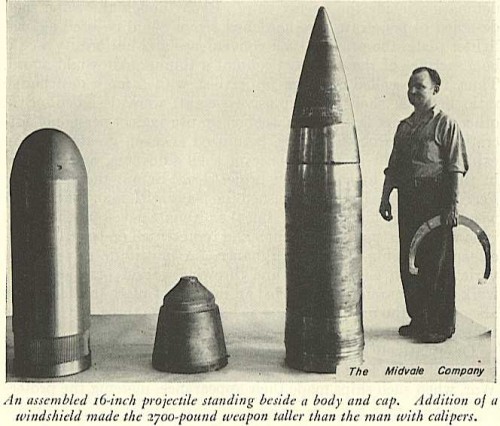

Figure 2: G7 Reference Projectile (Similar to Spitzer Design).

For the derivation to follow, I will use Equation 3 to model the variation in cd with velocity.

| Eq. 3 |

|

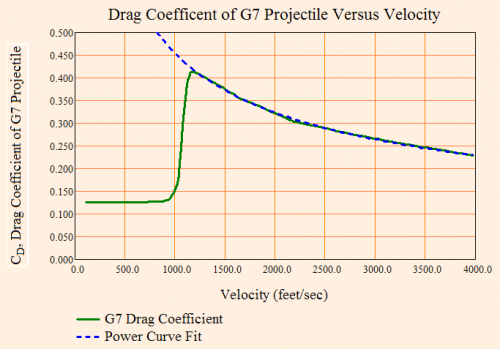

I will use Equation 4 to model the deceleration of the projectile with respect to velocity.

| Eq. 4 |

|

where m is the mass of the projectile and k is a generic constant I will use to aggregate all the projectile and atmospheric parameters ( ).

).

Derivation of Velocity Versus Range Equation

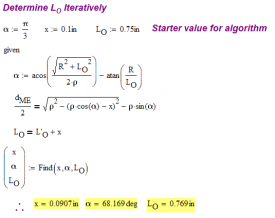

We can use the expression for the acceleration of the projectile (Equation 4), we can construct and solve a differential equation that relates velocity and position. Equation 5 shows the desired differential equation and how to solve it. This equation assumes that the projectile is moving horizontally, which is what Pejsa assumed. For bullets used in normal applications (e.g. target shooting, hunting), this is a good assumption for velocity. It is not a good assumption for bullet drop, which I will handle in a later post.

At this point, Pejsa introduces an interesting substitution. He defines a term F, which he calls the retardation coefficient. F provides a computationally simple yet accurate drag model (see this post for more information).

| Eq. 6 |

and and  |

We can substitute Equation 6 into Equation 5 to obtain Equation 7.

| Eq. 7 |

|

We can substitute Equation 6 into Equation 7 to derive a simple relationship between F and F0, which is shown in Equation 8.

| Eq. 8 |

|

Equation 7 allows us to compute the projectile velocity versus range, given values for F and n. In a later blog post, I will show how F and n can be estimated for standard projectiles.

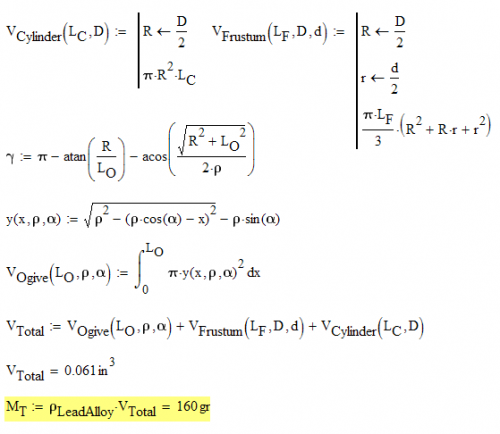

Empirical Comparison

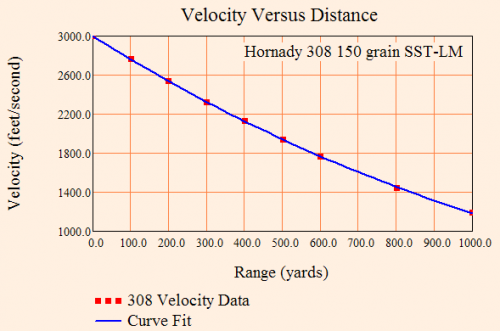

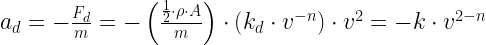

It is interesting to look at a real projectile and see how well this model fits the empirical data. Consider a Hornady 308 caliber, 150 grain, SST-LM. Figure 3 shows the data in a screen capture from Mathcad.

Figure 3: Velocity Versus Range Data for Hornady 308, 150 Grain, SST-LM

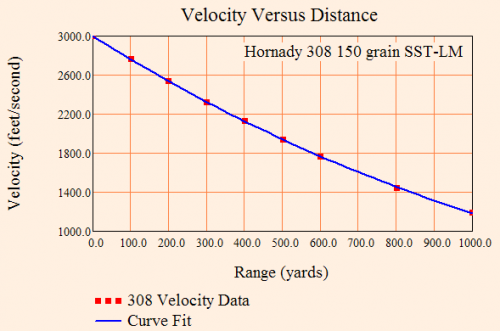

Using Mathcad, I fit the projectile velocity data to Equation 7 (n = 0.266 and F0 = 1227 yards) and plotted the fitted curve and the raw data in Figure 4.

Figure 4: Raw Hornady Data and Model Curve Fit Comparison.

Raw data from Ammo and Ballistics II (2nd Edition) by Forker (ISBN 1-57157-305-4).

The fit is excellent.

Conclusion

I presented a summary of the Pejsa derivation for the velocity of a projectile versus distance. The agreement between his equation and an arbitrarily chosen example was excellent. In subsequent posts, I will discuss other results from his model.